Recycled Plastic Granules: Plastics have become a ubiquitous part of our daily lives, with applications ranging from packaging materials to consumer goods. However, the widespread use of plastics has resulted in a serious environmental problem, with millions of tons of plastic waste being generated every year.

To address this issue, the recycling of plastic waste has become increasingly important. Recycling not only reduces the amount of waste in landfills but also conserves resources and reduces the environmental impact of plastic production.

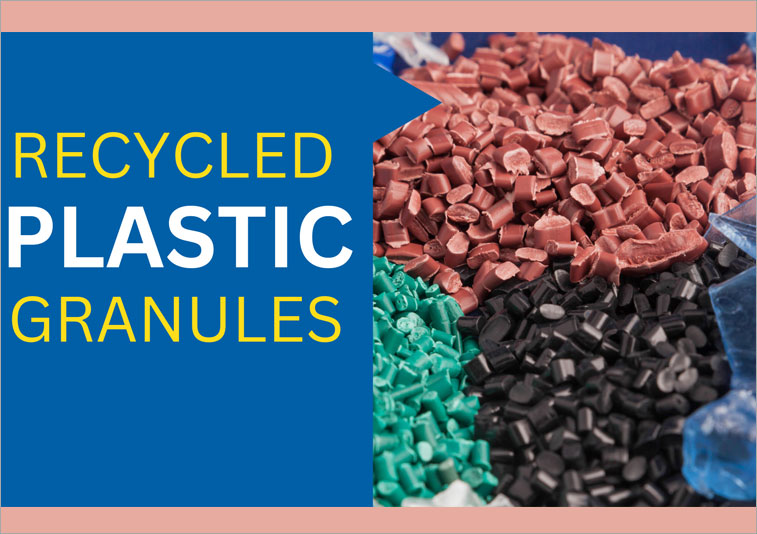

Recycled plastic granules are small pellets made from recycled plastic waste. They are the end product of the plastic recycling process and are used as a raw material in the production of new plastic products. The recycled plastic granules are made by melting down plastic waste, purifying it, and then shaping it into small pellets that are ready to be used in the manufacturing process.

The Process of Making Recycled Plastic Granules

1.Collection and Sorting of Plastic Waste The first step in the process of making recycled plastic granules is to collect and sort plastic waste. Plastic waste can come from a variety of sources, including household waste, industrial waste, and post-consumer waste. The waste is sorted based on the type of plastic it is made from, as different types of plastic have different properties and melting points.

2.Shredding and Washing Once the plastic waste has been sorted, it is then shredded into small pieces. The shredded plastic is then washed to remove any impurities, such as labels, adhesives, and dirt. This step is important to ensure that the recycled plastic granules are of a high quality and do not contain any contaminants that could affect the quality of the final product.

3.Melting and Extrusion The next step is to melt the purified plastic waste. The melted plastic is then extruded through a machine that shapes it into small pellets. The process of extrusion helps to remove any air pockets or impurities that may be present in the melted plastic.

4.Cooling and Pelletizing Once the plastic has been extruded, it is then cooled and pelletized. This process helps to solidify the plastic and give it a consistent shape and size. The recycled plastic granules are then ready to be used in the production of new plastic products.

Recycled plastic granules are a valuable solution to the problem of plastic waste. They not only help to reduce the amount of waste in landfills but also conserve resources and reduce the environmental impact of plastic production. The process of making recycled plastic granules is simple and effective and results in high-quality granules that can be used in the production of new plastic products. By using recycled plastic granules, we can help to create a more sustainable future for our planet.